PROJECT REQUIREMENTS

- design, develop and deliver a complete automated system for LASER welding of battery modules, in a very short period of time

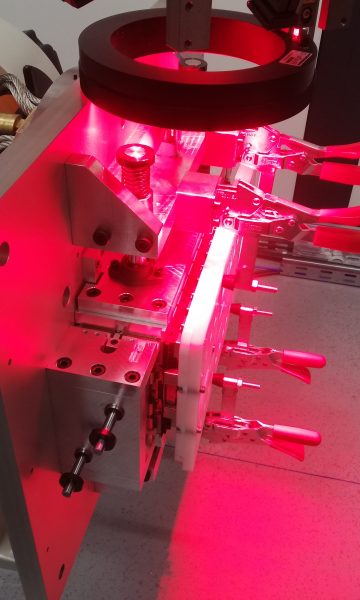

- ensure simplicity and repeatability of battery module assembly

- ensure the ease of replacing work pieces

- prevent incorrect module assembly

- complete integration of the production line

- easy operation for personnel

- ensure availability and traceability of all required process data

- connecting the system with the client’s ERP system

- traceability of all installed components

SOLUTION

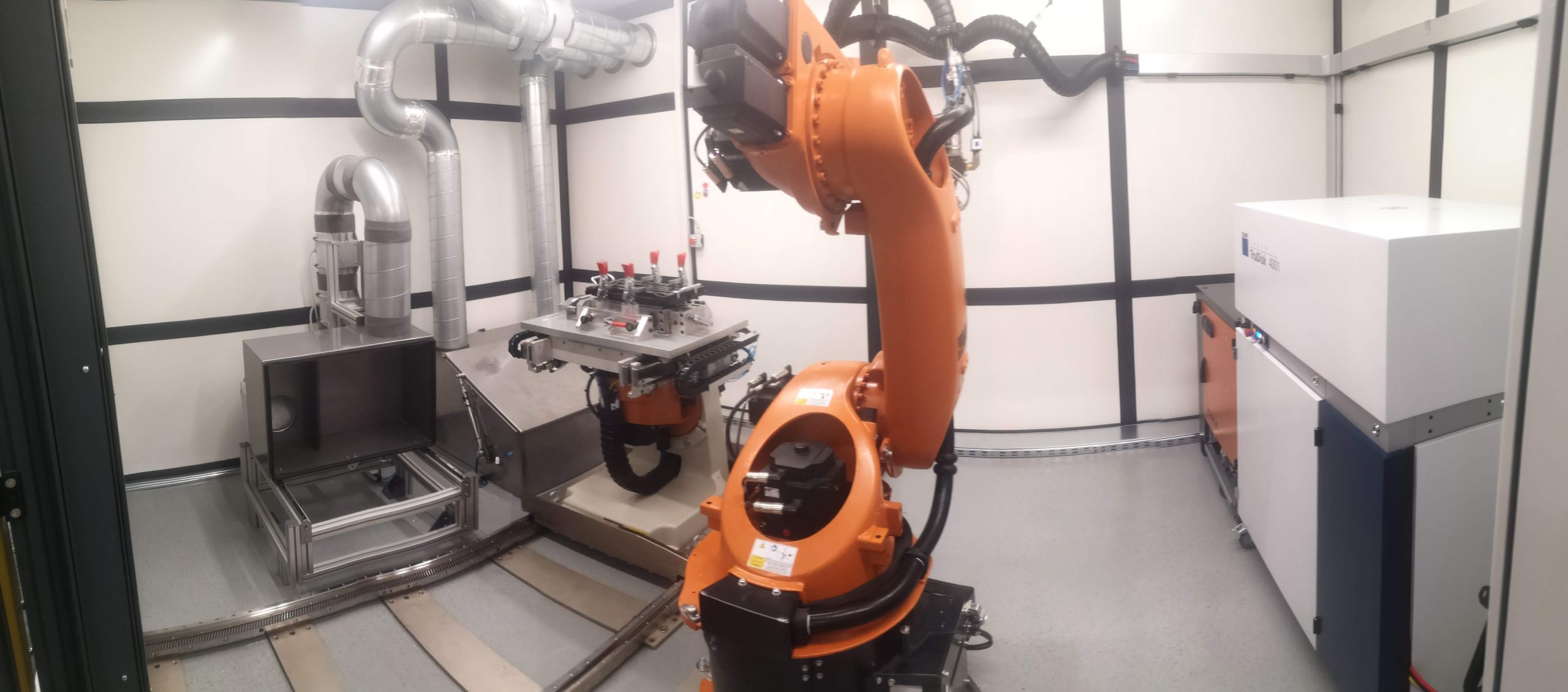

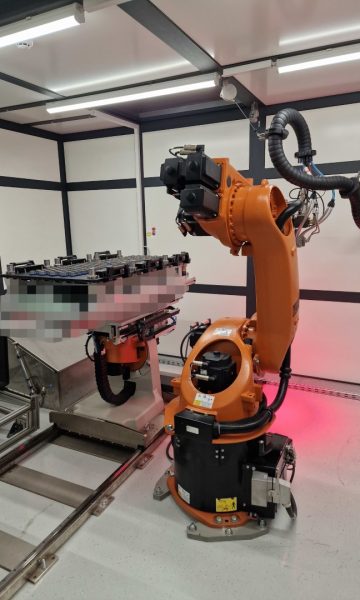

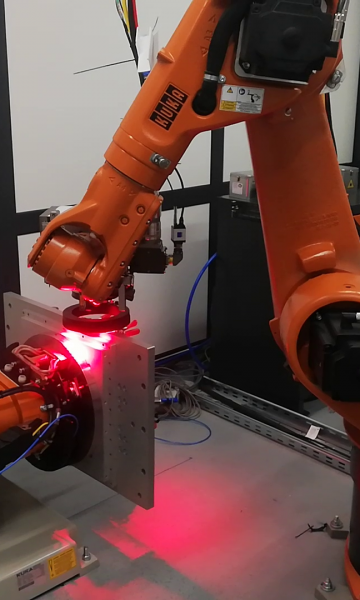

- 6-axis KUKA industrial robot with synchronized turn-tilt table

- CE certified laser welding booth

- system for the automated exchange of workpieces from the handling cart to the robotic cell

- program starting with one press of a button

- recording of all process parameters

- integration of the entire production line into one automated system

- SIEMENS PLC system for monitoring the robotic cell

- battery module fire extinguishing system

- battery cell polarity tester

- vision system for checking the workpiece compliance

Hunor